Solution

Contact NowSolution

Industry Solutions

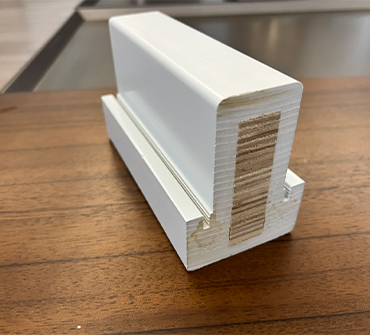

PVC DOOR FRAME VS WOOD DOOR FRAME

PVC door jambs have become a popular choice for people who want to install a door in their home or office. The reason for their growing popularity is their durability, affordability, and long-lasting quality. It comes as no surprise that PVC door jambs are the ultimate solution to all your door frame problems.

PVC door jambs are made from polyvinyl chloride, a synthetic plastic polymer. This material makes them resistant to water, moisture, termites, and other insects. Unlike wooden door frames, PVC door jambs do not rot or decay, which means that they require minimal maintenance and are easy to clean.

Advantages of PVC Door Jambs

1.Durability: PVC door jambs have a long lifespan and can withstand harsh weather conditions. They do not dent or scratch easily, making them an excellent choice for high-traffic areas.

2.Affordability: PVC door jambs cost less than wooden door frames, making them a budget-friendly option for homeowners.

3.Easy to install: PVC door jambs are lightweight and easy to install, which makes them a great option for people who prefer to do DIY projects.

4.Variety of designs: PVC door jambs are available in a wide range of designs and colors, which means that you can choose a style that complements your home decor.

5.Termite-proof: Unlike wooden door frames, PVC door jambs do not attract termites or other insects that can cause structural damage to your home.

PVC door jambs are made from polyvinyl chloride, a synthetic plastic polymer. This material makes them resistant to water, moisture, termites, and other insects. Unlike wooden door frames, PVC door jambs do not rot or decay, which means that they require minimal maintenance and are easy to clean.

Advantages of PVC Door Jambs

1.Durability: PVC door jambs have a long lifespan and can withstand harsh weather conditions. They do not dent or scratch easily, making them an excellent choice for high-traffic areas.

2.Affordability: PVC door jambs cost less than wooden door frames, making them a budget-friendly option for homeowners.

3.Easy to install: PVC door jambs are lightweight and easy to install, which makes them a great option for people who prefer to do DIY projects.

4.Variety of designs: PVC door jambs are available in a wide range of designs and colors, which means that you can choose a style that complements your home decor.

5.Termite-proof: Unlike wooden door frames, PVC door jambs do not attract termites or other insects that can cause structural damage to your home.

Why Choose PVC Door Frames: A Wise Choice for Modern Homes

In modern home decoration, the choice of door frames is often overlooked, yet it has a profound impact on the overall effect, durability, and living experience. When faced with a variety of materials such as solid wood, aluminum alloy, stainless steel, and PVC, PVC door frames are becoming the preferred choice for more and more families and designers due to their unique comprehensive advantages. It is not just a material, but a modern solution that integrates practicality, economy, and aesthetics.

Superior Performance, Meeting Diverse Challenges

1.Excellent Moisture Resistance and Corrosion Resistance

PVC (polyvinyl chloride) is a high-molecular polymer that naturally resists moisture erosion. In humid environments such as bathrooms, kitchens, basements, or the rainy season in southern regions, traditional wooden door frames are prone to warping, mold, and even rotting. PVC door frames, on the other hand, remain stable and never rust or corrode, fundamentally solving the problems caused by humid environments and extending the lifespan of the door.

2.Superior Durability and Low Maintenance Costs

PVC material is high in strength, impact-resistant, and not easily scratched. It will not crack or warp like wood, nor does it require worrying about rust like wrought iron. Daily cleaning and maintenance are extremely simple; a simple wipe with a damp cloth is all it takes to keep it looking brand new, saving the hassle and expense of painting and repairs, truly achieving “one-time installation, long-term peace of mind.”

3.Environmentally Friendly and Healthy, Safe Living

High-quality PVC door frame materials are stable, non-toxic, and odorless, releasing no formaldehyde or other harmful substances during production and use. This provides a safer and healthier environment for families with children, the elderly, or members with allergies. Furthermore, PVC materials are recyclable, aligning with the concept of green and sustainable development.

Aesthetically Pleasing and Economical, Meeting Modern Needs

1.Rich Decorative Effects

Modern manufacturing processes allow PVC door frames to realistically mimic the textures and feel of various woods, such as oak, walnut, and teak, and offer a variety of color options including pure white, light gray, and dark brown. Whether it’s a Nordic minimalist, modern light luxury, or Chinese classical style, a perfectly matching product can be found, achieving a unity of beauty and practicality.

2.Highly Competitive Price-Performance Ratio

Compared to high-quality solid wood and high-end aluminum alloy, PVC door frames have a significant price advantage. It offers a comparable appearance and superior moisture resistance at a more economical cost, allowing budget-conscious renovations to achieve high-quality results, making it a highly cost-effective choice.

3.Excellent Sealing and Sound Insulation Performance

PVC door frames can be tightly integrated with sealing strips, effectively blocking wind, sand, dust, noise, and insects, improving the tranquility and cleanliness of indoor spaces, and enhancing living comfort.

Widely Applicable and Easy to Install

1.Highly Versatile Application Scenarios

PVC door frames are suitable for almost all interior doors: bedrooms, studies, bathrooms, kitchens, balcony partitions, etc. Their advantages are irreplaceable, especially in spaces with high humidity, large temperature differences, and frequent cleaning.

2.Convenient Processing and Installation

PVC material is lightweight and easy to cut and assemble. The installation process is faster and cleaner than traditional wooden frames, effectively shortening the construction period and reducing dust and noise pollution during on-site construction.

Smart Choices and Considerations

Of course, there are a few things to keep in mind when choosing PVC door frames:

Quality is key: Always choose reputable brands, ensuring the material is brand new, environmentally friendly PVC, meets wall thickness standards, and has a reinforced internal structure to guarantee sufficient strength and durability.

Style Matching: Choose colors and textures that match the overall decor to ensure harmony and unity.

Professional Installation: Hire a professional installer to ensure the door frame is vertical, level, and tightly sealed, maximizing its performance.

Choosing PVC door frames is not just about cost; it’s also an endorsement of a modern, rational lifestyle. It represents a pursuit of durability, peace of mind, health, and aesthetics in the details of home life. When you weigh every aspect of your home’s decor, PVC door frames, with their “simplicity over complexity” characteristic, provide a solid, reliable, and elegant frame—defining not only the outline of the doorway but also, in a sense, defining a relaxed and unhurried quality of modern living.

On the road to creating your ideal home, let PVC door frames become your trustworthy silent guardians, silently witnessing the warmth and peace of your home as time goes by.

Superior Performance, Meeting Diverse Challenges

1.Excellent Moisture Resistance and Corrosion Resistance

PVC (polyvinyl chloride) is a high-molecular polymer that naturally resists moisture erosion. In humid environments such as bathrooms, kitchens, basements, or the rainy season in southern regions, traditional wooden door frames are prone to warping, mold, and even rotting. PVC door frames, on the other hand, remain stable and never rust or corrode, fundamentally solving the problems caused by humid environments and extending the lifespan of the door.

2.Superior Durability and Low Maintenance Costs

PVC material is high in strength, impact-resistant, and not easily scratched. It will not crack or warp like wood, nor does it require worrying about rust like wrought iron. Daily cleaning and maintenance are extremely simple; a simple wipe with a damp cloth is all it takes to keep it looking brand new, saving the hassle and expense of painting and repairs, truly achieving “one-time installation, long-term peace of mind.”

3.Environmentally Friendly and Healthy, Safe Living

High-quality PVC door frame materials are stable, non-toxic, and odorless, releasing no formaldehyde or other harmful substances during production and use. This provides a safer and healthier environment for families with children, the elderly, or members with allergies. Furthermore, PVC materials are recyclable, aligning with the concept of green and sustainable development.

Aesthetically Pleasing and Economical, Meeting Modern Needs

1.Rich Decorative Effects

Modern manufacturing processes allow PVC door frames to realistically mimic the textures and feel of various woods, such as oak, walnut, and teak, and offer a variety of color options including pure white, light gray, and dark brown. Whether it’s a Nordic minimalist, modern light luxury, or Chinese classical style, a perfectly matching product can be found, achieving a unity of beauty and practicality.

2.Highly Competitive Price-Performance Ratio

Compared to high-quality solid wood and high-end aluminum alloy, PVC door frames have a significant price advantage. It offers a comparable appearance and superior moisture resistance at a more economical cost, allowing budget-conscious renovations to achieve high-quality results, making it a highly cost-effective choice.

3.Excellent Sealing and Sound Insulation Performance

PVC door frames can be tightly integrated with sealing strips, effectively blocking wind, sand, dust, noise, and insects, improving the tranquility and cleanliness of indoor spaces, and enhancing living comfort.

Widely Applicable and Easy to Install

1.Highly Versatile Application Scenarios

PVC door frames are suitable for almost all interior doors: bedrooms, studies, bathrooms, kitchens, balcony partitions, etc. Their advantages are irreplaceable, especially in spaces with high humidity, large temperature differences, and frequent cleaning.

2.Convenient Processing and Installation

PVC material is lightweight and easy to cut and assemble. The installation process is faster and cleaner than traditional wooden frames, effectively shortening the construction period and reducing dust and noise pollution during on-site construction.

Smart Choices and Considerations

Of course, there are a few things to keep in mind when choosing PVC door frames:

Quality is key: Always choose reputable brands, ensuring the material is brand new, environmentally friendly PVC, meets wall thickness standards, and has a reinforced internal structure to guarantee sufficient strength and durability.

Style Matching: Choose colors and textures that match the overall decor to ensure harmony and unity.

Professional Installation: Hire a professional installer to ensure the door frame is vertical, level, and tightly sealed, maximizing its performance.

Choosing PVC door frames is not just about cost; it’s also an endorsement of a modern, rational lifestyle. It represents a pursuit of durability, peace of mind, health, and aesthetics in the details of home life. When you weigh every aspect of your home’s decor, PVC door frames, with their “simplicity over complexity” characteristic, provide a solid, reliable, and elegant frame—defining not only the outline of the doorway but also, in a sense, defining a relaxed and unhurried quality of modern living.

On the road to creating your ideal home, let PVC door frames become your trustworthy silent guardians, silently witnessing the warmth and peace of your home as time goes by.

Why Choose PVC Composite Door Jamb Moulding

Choosing a PVC door jamb offers several advantages, making it a popular choice for modern homes and buildings. Here’s why you might consider it:

Durability: PVC (polyvinyl chloride) is highly resistant to rot, corrosion, and termites, unlike wood or metal. It doesn’t warp, crack, or degrade in harsh weather, making it ideal for humid or rainy climates.

Low Maintenance: Unlike wood, PVC doesn’t require painting, sealing, or varnishing. A simple wipe-down with soapy water keeps it looking new, saving time and long-term costs.

Cost-Effective: PVC is generally cheaper than high-quality wood or metal frames. Its longevity and minimal upkeep further reduce lifetime expenses.

Energy Efficiency: PVC is a natural insulator, helping to retain indoor heat or cool air. This improves energy efficiency and lowers utility bills.

Moisture & Weather Resistance: Perfect for bathrooms, kitchens, or coastal areas, PVC resists water damage, mold, and UV rays, maintaining its integrity over time.

Aesthetic Flexibility: Available in various colors, textures (including wood-grain finishes), and styles, PVC frames can match modern or traditional designs without fading.

Eco-Friendly Option: While PVC production has environmental concerns, it’s recyclable and reduces the need for deforestation (unlike wood jambs).

Lightweight & Easy Installation: PVC’s lightweight nature simplifies transportation and installation compared to heavier materials like steel.

Durability: PVC (polyvinyl chloride) is highly resistant to rot, corrosion, and termites, unlike wood or metal. It doesn’t warp, crack, or degrade in harsh weather, making it ideal for humid or rainy climates.

Low Maintenance: Unlike wood, PVC doesn’t require painting, sealing, or varnishing. A simple wipe-down with soapy water keeps it looking new, saving time and long-term costs.

Cost-Effective: PVC is generally cheaper than high-quality wood or metal frames. Its longevity and minimal upkeep further reduce lifetime expenses.

Energy Efficiency: PVC is a natural insulator, helping to retain indoor heat or cool air. This improves energy efficiency and lowers utility bills.

Moisture & Weather Resistance: Perfect for bathrooms, kitchens, or coastal areas, PVC resists water damage, mold, and UV rays, maintaining its integrity over time.

Aesthetic Flexibility: Available in various colors, textures (including wood-grain finishes), and styles, PVC frames can match modern or traditional designs without fading.

Eco-Friendly Option: While PVC production has environmental concerns, it’s recyclable and reduces the need for deforestation (unlike wood jambs).

Lightweight & Easy Installation: PVC’s lightweight nature simplifies transportation and installation compared to heavier materials like steel.

Why Choose Composite Brick Molds: Unlocking the Key to Efficiency and Precision in Modern Construction

In the wave of innovation in modern building materials, molds, as the “mother” of products, directly determine the quality, efficiency, and cost of the final components through their technological level. Among numerous mold technologies, composite brick molds, with their comprehensive and superior performance, are moving from behind the scenes to the forefront, becoming a core force driving the construction industry towards high efficiency, energy conservation, and customization.

I.Composite Molds: Technological Innovation Beyond “Molds”

Composite brick molds do not refer to a single-form product, but rather a type of solution that achieves performance exceeding that of traditional single-material molds through composite design in materials or structures. Its core concept is to break through the limitations of traditional steel, wood, or plastic molds, leveraging their strengths to create a synergistic effect of “1+1>2.” From a technological perspective, it mainly manifests in two forms:

Material Composite Type: For example, a layer of wear-resistant, elastic polymer material (such as special rubber, polyurethane, etc.) is bonded to the inner surface of a traditional steel mold using an adhesive, forming a mold cavity that combines rigidity and flexibility. This material gives the mold excellent impact resistance, tear resistance, and non-stick properties.

Structural-functional composite type: The mold itself is part of the product forming logic. For example, extrusion composite molds, through unique transition and forming section designs, can extrude bricks made of different materials (such as clay layers and shale brick bodies) in one go. There is also an innovative “brick-mold integration” design, where the brick itself has a mortise and tenon structure, which interlocks during construction to form a stable “mold,” into which a functional wall can be formed after filling.

II.Core Advantages of Choosing Composite Brick Molds

Choosing composite brick molds is essentially choosing a more forward-looking production and construction model. Its core advantages can be clearly demonstrated from the following dimensions:

1.Superior Product Performance and Finished Product Quality

The primary task of composite molds is to produce building components with superior performance.

Achieving multi-functional composite products: It can precisely form bricks with multi-layered composite structures. For example, “retro high-performance bricks” with a rustic clay-like surface and a high-strength shale interior can be produced, perfectly balancing aesthetics and mechanical requirements; or self-insulating concrete blocks with built-in polystyrene insulation boards can be manufactured to completely block thermal bridges, significantly improving the energy efficiency of walls.

Significantly improved product precision and consistency: The elastic lining in the composite mold effectively absorbs and buffers the stress of material compression, reducing problems such as missing corners and cracks caused by minor misalignments or hard friction, significantly improving yield and dimensional accuracy. A stable molding environment ensures the uniformity of quality for each batch of products.

2.Unprecedented production efficiency and economy

In today’s competitive landscape where cost and efficiency determine competitiveness, the advantages of composite molds are particularly prominent.

Revolutionary high-efficiency production process: The most significant efficiency improvement comes from one-step molding technology. Traditional composite bricks require step-by-step production and bonding, while advanced extrusion composite molds can achieve simultaneous co-extrusion and one-step molding of different material layers within the same mold, eliminating multiple intermediate processes and greatly simplifying the production process.

Significantly Longer Mold Life and Reduced Maintenance Costs: Traditional steel molds are brittle and easily worn. Molds lined with composite polymer materials exhibit a qualitative leap in wear resistance and impact resistance. This not only significantly extends the mold’s lifespan and reduces the frequency of mold purchase and replacement, but also improves overall production efficiency by reducing downtime for maintenance.

3.Strong Design Freedom and Construction Convenience: Composite mold technology opens up new possibilities for architectural design and construction.

Enabling the Manufacturing of Complex and Irregularly Shaped Components: Innovative structures such as “brick-mold integration” make it possible to manufacture multifunctional bricks with complex mortise and tenon joints, holes, or irregular curved surfaces. These bricks are both structural components and construction molds, greatly enriching the aesthetic language of building facades and wall structures.

Promoting Simplified and Standardized Construction Processes: Using pre-formed composite bricks (such as self-insulating bricks and brick-mold integrated bricks) for construction can reduce complex processes such as on-site formwork and external insulation, achieving integrated completion of wall structure and insulation functions. This not only shortens the construction period and reduces overall construction costs, but also reduces the quality risks associated with cross-disciplinary work.

III. Core Application Scenarios: From Inheritance to Innovation

Composite brick mold technology, due to its unique advantages, is playing an irreplaceable role in specific fields:

Historical Building Restoration and Antique-Style New Construction: For ancient building restoration and antique-style street construction projects that need to maintain the traditional appearance of clay bricks while meeting modern structural strength and safety standards, composite bricks, which can replicate the appearance and improve strength, are an ideal choice. This relies entirely on its specialized composite extrusion molds.

High-Performance Energy-Saving Buildings: In today’s pursuit of ultra-low energy consumption and near-zero energy consumption buildings, molds used to produce fully thermally insulating composite blocks are key technical equipment for constructing efficient building envelopes and meeting the latest mandatory energy-saving standards (such as energy saving rates of 75% or higher).

Modern Innovative Building Systems: Under the trend of advocating green and rapid construction and modular design, products such as integrated brick-mold and irregularly shaped multifunctional bricks provide new, flexible, and environmentally friendly technical options for rural construction, distinctive landscape walls, and low-carbon buildings.

1.Future Trends: Intelligentization and Sustainability The development of composite brick mold technology is booming, and in the future, it will be more closely integrated with two major trends:

Integration with Digital and Intelligent Manufacturing: Mold design will be fully optimized using CAE simulation, and its production and use processes will increasingly integrate sensors and intelligent control systems to achieve precise control of pressure, temperature, and material flow rate, moving towards a new stage of “intelligent molds.”

Deepening the Concept of Green Sustainability: Molds will focus more on utilizing solid waste such as coal gangue and shale, as well as industrial by-products such as slag and stone powder as production raw materials. At the same time, the “brick-mold integration” construction model, representing detachable and recyclable components, perfectly responds to the strategic need for reducing carbon emissions in the construction industry.

Choosing composite brick molds is far more than a simple tool upgrade. It represents a firm choice for a high-quality, high-efficiency, and highly flexible production method for building products, and an unremitting pursuit of the optimal solution integrating architectural aesthetics, performance, energy conservation, and ease of construction. From replicating the texture of history to building green living spaces for the future, composite brick molds, with their ingenious “composite” wisdom, are quietly shaping the solid structure of the architectural world and becoming the key to propelling the industry toward a more advanced and sustainable future.

I.Composite Molds: Technological Innovation Beyond “Molds”

Composite brick molds do not refer to a single-form product, but rather a type of solution that achieves performance exceeding that of traditional single-material molds through composite design in materials or structures. Its core concept is to break through the limitations of traditional steel, wood, or plastic molds, leveraging their strengths to create a synergistic effect of “1+1>2.” From a technological perspective, it mainly manifests in two forms:

Material Composite Type: For example, a layer of wear-resistant, elastic polymer material (such as special rubber, polyurethane, etc.) is bonded to the inner surface of a traditional steel mold using an adhesive, forming a mold cavity that combines rigidity and flexibility. This material gives the mold excellent impact resistance, tear resistance, and non-stick properties.

Structural-functional composite type: The mold itself is part of the product forming logic. For example, extrusion composite molds, through unique transition and forming section designs, can extrude bricks made of different materials (such as clay layers and shale brick bodies) in one go. There is also an innovative “brick-mold integration” design, where the brick itself has a mortise and tenon structure, which interlocks during construction to form a stable “mold,” into which a functional wall can be formed after filling.

II.Core Advantages of Choosing Composite Brick Molds

Choosing composite brick molds is essentially choosing a more forward-looking production and construction model. Its core advantages can be clearly demonstrated from the following dimensions:

1.Superior Product Performance and Finished Product Quality

The primary task of composite molds is to produce building components with superior performance.

Achieving multi-functional composite products: It can precisely form bricks with multi-layered composite structures. For example, “retro high-performance bricks” with a rustic clay-like surface and a high-strength shale interior can be produced, perfectly balancing aesthetics and mechanical requirements; or self-insulating concrete blocks with built-in polystyrene insulation boards can be manufactured to completely block thermal bridges, significantly improving the energy efficiency of walls.

Significantly improved product precision and consistency: The elastic lining in the composite mold effectively absorbs and buffers the stress of material compression, reducing problems such as missing corners and cracks caused by minor misalignments or hard friction, significantly improving yield and dimensional accuracy. A stable molding environment ensures the uniformity of quality for each batch of products.

2.Unprecedented production efficiency and economy

In today’s competitive landscape where cost and efficiency determine competitiveness, the advantages of composite molds are particularly prominent.

Revolutionary high-efficiency production process: The most significant efficiency improvement comes from one-step molding technology. Traditional composite bricks require step-by-step production and bonding, while advanced extrusion composite molds can achieve simultaneous co-extrusion and one-step molding of different material layers within the same mold, eliminating multiple intermediate processes and greatly simplifying the production process.

Significantly Longer Mold Life and Reduced Maintenance Costs: Traditional steel molds are brittle and easily worn. Molds lined with composite polymer materials exhibit a qualitative leap in wear resistance and impact resistance. This not only significantly extends the mold’s lifespan and reduces the frequency of mold purchase and replacement, but also improves overall production efficiency by reducing downtime for maintenance.

3.Strong Design Freedom and Construction Convenience: Composite mold technology opens up new possibilities for architectural design and construction.

Enabling the Manufacturing of Complex and Irregularly Shaped Components: Innovative structures such as “brick-mold integration” make it possible to manufacture multifunctional bricks with complex mortise and tenon joints, holes, or irregular curved surfaces. These bricks are both structural components and construction molds, greatly enriching the aesthetic language of building facades and wall structures.

Promoting Simplified and Standardized Construction Processes: Using pre-formed composite bricks (such as self-insulating bricks and brick-mold integrated bricks) for construction can reduce complex processes such as on-site formwork and external insulation, achieving integrated completion of wall structure and insulation functions. This not only shortens the construction period and reduces overall construction costs, but also reduces the quality risks associated with cross-disciplinary work.

III. Core Application Scenarios: From Inheritance to Innovation

Composite brick mold technology, due to its unique advantages, is playing an irreplaceable role in specific fields:

Historical Building Restoration and Antique-Style New Construction: For ancient building restoration and antique-style street construction projects that need to maintain the traditional appearance of clay bricks while meeting modern structural strength and safety standards, composite bricks, which can replicate the appearance and improve strength, are an ideal choice. This relies entirely on its specialized composite extrusion molds.

High-Performance Energy-Saving Buildings: In today’s pursuit of ultra-low energy consumption and near-zero energy consumption buildings, molds used to produce fully thermally insulating composite blocks are key technical equipment for constructing efficient building envelopes and meeting the latest mandatory energy-saving standards (such as energy saving rates of 75% or higher).

Modern Innovative Building Systems: Under the trend of advocating green and rapid construction and modular design, products such as integrated brick-mold and irregularly shaped multifunctional bricks provide new, flexible, and environmentally friendly technical options for rural construction, distinctive landscape walls, and low-carbon buildings.

1.Future Trends: Intelligentization and Sustainability The development of composite brick mold technology is booming, and in the future, it will be more closely integrated with two major trends:

Integration with Digital and Intelligent Manufacturing: Mold design will be fully optimized using CAE simulation, and its production and use processes will increasingly integrate sensors and intelligent control systems to achieve precise control of pressure, temperature, and material flow rate, moving towards a new stage of “intelligent molds.”

Deepening the Concept of Green Sustainability: Molds will focus more on utilizing solid waste such as coal gangue and shale, as well as industrial by-products such as slag and stone powder as production raw materials. At the same time, the “brick-mold integration” construction model, representing detachable and recyclable components, perfectly responds to the strategic need for reducing carbon emissions in the construction industry.

Choosing composite brick molds is far more than a simple tool upgrade. It represents a firm choice for a high-quality, high-efficiency, and highly flexible production method for building products, and an unremitting pursuit of the optimal solution integrating architectural aesthetics, performance, energy conservation, and ease of construction. From replicating the texture of history to building green living spaces for the future, composite brick molds, with their ingenious “composite” wisdom, are quietly shaping the solid structure of the architectural world and becoming the key to propelling the industry toward a more advanced and sustainable future.